Forge Your Path to Success

Are you ready to kickstart your journey towards success with real-world experience in the dynamic field of manufacturing?

Real-world experience Gain hands-on experience working with state-of-the-art manufacturing equipment, reinforcing what you’ve learned in the classroom. | Paid internship opportunities Earn money while you learn! Our internship program offers paid positions with SAMP member companies, providing you with valuable income and invaluable experience. | Well-rounded education As PCC students, this internship complements your academic studies by providing industry-relevant experience. You’re not just learning theories but actively engaging in the practical aspects of the industry. |

Take control of your future

Pave the way for success in the manufacturing sector. Through this internship program, you’ll not only develop technical skills but also cultivate essential soft skills such as teamwork, communication, and problem-solving — essential for thriving in any career path.

Many machinists eventually own their own shops. The typical shop is founded by a 35-year-old machinist and brings in sales of $2 million per year.

How it works

Interested PCC-enrolled students complete the application process and are then invited to attend SAMP Employer Interview Day to meet with SAMP member companies. Internship offers are extended afterwards, and once the offer is accepted by the student, the paid internship program gets underway. Over the course of the internship program, the member company reinforces concepts students learn in the classroom and gives real-world experience working with modern, state-of-the-art manufacturing equipment.

Get started to forge your path to success.

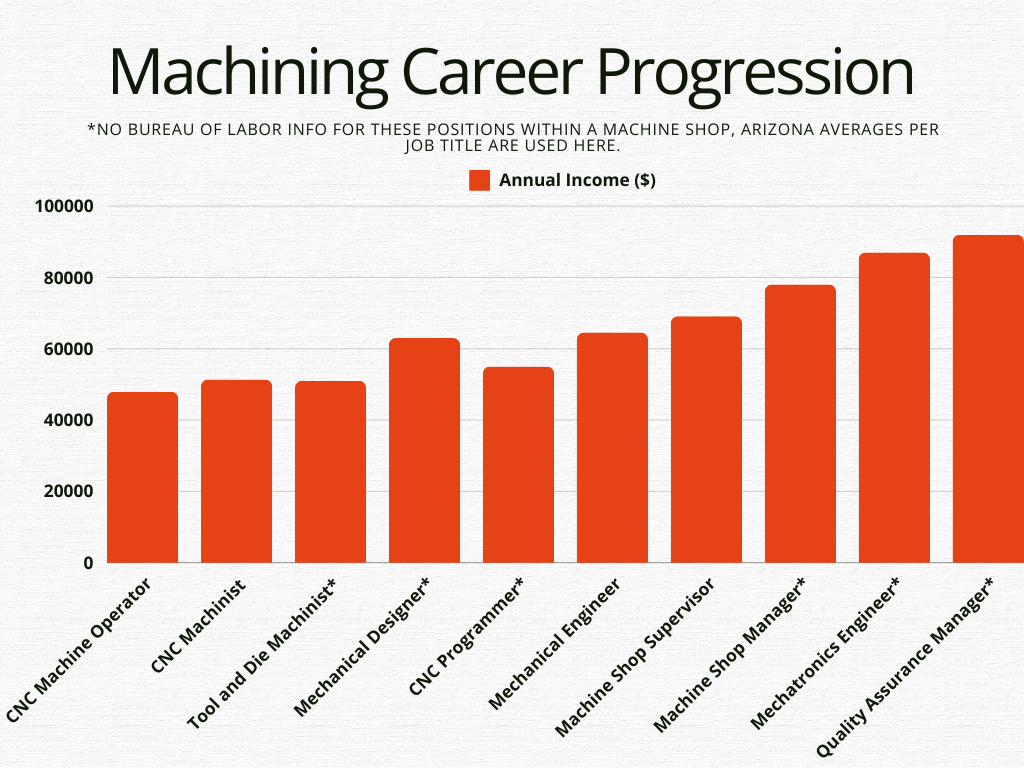

See What Your Future Could Be

CNC Operator Entry-level no set-up skills, hired out of high school machine shop programs or basic community programs. CNC Machine Operator Intermediate set-up skills (basic to moderately complex set-up skills). CNC Machinist Moderately complex to complex set-up skills. Ten plus years hands-on experience. Tool and Die Machinist Moderately complex to complex set-up skills. Ten plus years hands-on experience. Mechanical Designer Uses modeling software, such as Solid Works to develop blue print drawings from engineering design concepts. | CNC Programmer Programs CNC machines. Utilizes programming software such as MasterCam, Gibbs and Espirit, to name a few. Mechanical Engineer Develops design concepts, ensures their manufacturability and may develop their own blue print drawings and job packages. Machine Shop Supervisor Typically has 15 plus years hands-on experience. Machine Shop Manager Has overall responsibility for the Machine Shop in addition to pricing and quoting jobs to customers. |

Manufacturing Career Information

U.S. manufacturers are on-shoring jobs right now and ready to grow with you. Why should you consider manufacturing as a career path?

-

Earn good money immediately — with plenty of opportunities to grow into great money in the future.

-

Work anywhere with skills and expertise that can take you around the world. Manufacturers want to invest in workforce leaders like YOU.

-

Be an industrial metaverse influencer and harness advanced technology like VR, AI, robotics, digital twins, 3D scanning & modeling, IoT and more.

Stay flexible. By focusing on productivity and a healthy work/life balance, many manufacturers offer flexible schedules, including remote work, compressed workweeks and more.